VARIM

VBK has a capability to process any complex shapes in Vacuum Infusion process without limitation to size. Using skilled resources with standard vacuum consumables, applicable resin and glass ratio we can achieve high-quality products with consistency in weight and thickness.

We have manufactured more than 5000 parts across various sectors.

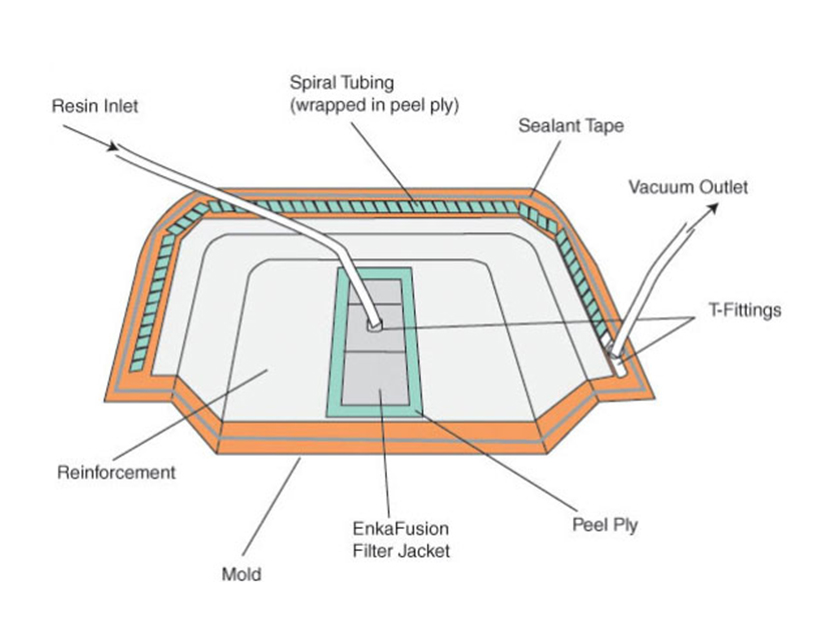

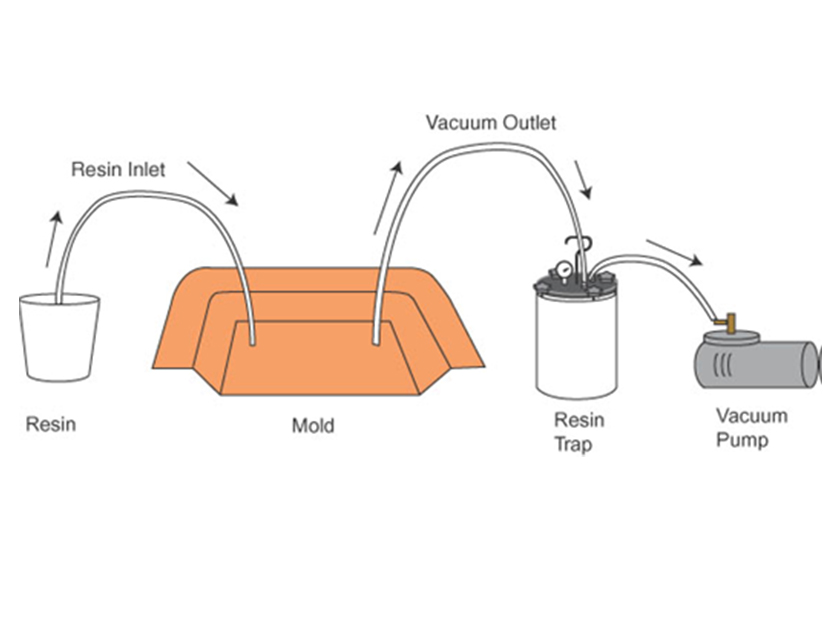

Initially releaser will be applied in the mould and gelcoat with recommended RAL shade is applied onto the surface of a mould for the outer finish Fiber reinforcements are placed in a mould as per the layer sequence and sealed with Vacuum film and sealant tape. A vacuum is applied before resin is introduced Once a complete vacuum is achieved, the resin is literally sucked into the laminate via carefully placed tubing. Vacuum bagging greatly improves the fiber-to-resin ratio, and results in a stronger and lighter product.

PROS

- Higher strength and stiffness

- No resin entrapped air/ very low voids

- Very consistent laminate with great process control

- Minimal part shrinkage with good surface profile and accuracy

- Can have good outside and inside surfaces

- Efficient to laminate complex fiber layers, ribs, inserts and cores

- Faster cycle time

Related Products

We are always ready to answer your questions. So feel free to contact us